Introduction

Soybean phospholipids are by-products of soybean oil refining process. Phospholipids composition can be affected by the oil refining processes and may decrease after frost. The lipase may contribute to phospholipids decrease during storage. Other major compositions in soybean phospholipids include water, pigment, galactosyl glyceride, glycolipids, carbohydrates, sterols and tocopherol etc.

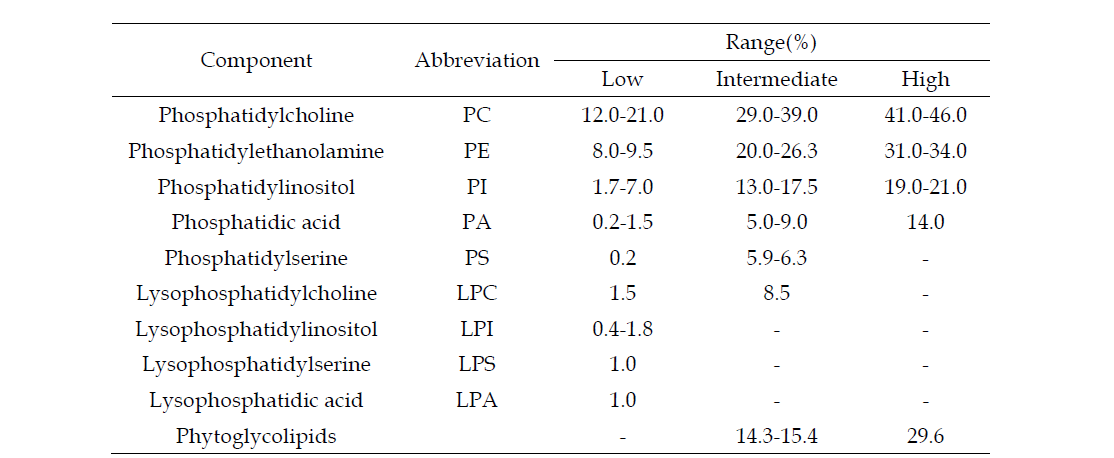

Commercial Crude soybean lecithin oil is a complex mixture of 65-75% phospholipids together with triglycerides and smaller amounts of other substances. The rest of the containing is soy bean oil.The major phospholipids include: phosphatidylcholine (PC), phosphatidylethanolamine (PE), phosphatidylinositol (PI), phosphatidylserine (PS) and phosphatidic acid (PA) in soybean phospholipids.

Production of powdered soybean phospholipids:

Crude soy Lecithin Oil contains about 50-65% phospholipids, which limit their application due to the high content of other substances such as fatty acids, soy bean oil. After the purification and refining of concentrated phospholipids, high purity powder phospholipids are produced. The methods for producing high purity powder phospholipids are: solvent extraction, ultra filtration purification, supercritical carbon dioxide extraction. But acetone solvent extraction is by far the most widely used method in the industry.

Extraction and separation of soybean phospholipids:

Soybean phospholipids contain different components in the solubility of organic solvents. This makes it possible to separate and purification the ingredients in it. PC is more soluble in alcohol, while PE and solubility are smaller. The PC can be purified with alcohol as a solvent. The concentration of PC can be increased to more than 60%. By using different organic solvents, a single component of phospholipids can be isolated and purified, e.g. PC phospholipids, rich in PS phospholipids, up to a purity of more than 95%.

Orison Chemicals Limited

Yihang Int'l Bldg No.5,Binhai, Tianjin, China.

Tel: +86 22 25600945

E-mail:info@orisonchem.com

Web: www.orisonchem.com